Your Brazing refrigerant lines without nitrogen images are ready. Brazing refrigerant lines without nitrogen are a topic that is being searched for and liked by netizens today. You can Get the Brazing refrigerant lines without nitrogen files here. Download all free photos and vectors.

If you’re looking for brazing refrigerant lines without nitrogen images information linked to the brazing refrigerant lines without nitrogen topic, you have visit the ideal blog. Our website frequently provides you with hints for refferencing the maximum quality video and image content, please kindly surf and find more enlightening video content and graphics that match your interests.

Brazing Refrigerant Lines Without Nitrogen. They indicate that failure to do so in a R410A system is worse as the oils may loosen the build up causing it to travel and block. PurgeBrazing heat causes the copper tubing to oxidize. Using gas to purge in my eyes is worthless wasteful and. Take this step during installation and.

Hvac Tools Brazing With Nitrogen 101 Rochester Heating Air Conditioning Serves Hvac Tools Refrigeration And Air Conditioning Heating And Air Conditioning From pinterest.com

Hvac Tools Brazing With Nitrogen 101 Rochester Heating Air Conditioning Serves Hvac Tools Refrigeration And Air Conditioning Heating And Air Conditioning From pinterest.com

While inserting nitrogen into the refrigerant piping. When youre doing this youve got to constantly. The metering device could get clogged. It is very thin and forms in the area of the heated joint so it is just not the joint but also the pipe itself where this can form. The nitrogen and argon are inert and while we dont want much of them inside a refrigeration system they dont react with the oil refrigerant and metals in the system like oxygen and water vapor can and often do. Before brazing or soldering any pipe it is important to fit the pipe and clean it.

Keep in mind that you need to FLOW nitrogen not PRESSURIZE with nitrogen while brazing otherwise you never get the joints to hold.

Two of the 4 lines had leaks and you could hear the refrigerant leaking. They do not offer the required strength and ductility. There is also a definite plus in not having to carry the nitrogen. However a tinsilver alloy is a viable option and offers some distinct advantage over brazing. The nitrogen and argon are inert and while we dont want much of them inside a refrigeration system they dont react with the oil refrigerant and metals in the system like oxygen and water vapor can and often do. After cleaning apply flux to the inner and outer joints.

Source: nttinc.com

Source: nttinc.com

With six percent silver this type of brazing rod starts to melt at 1190 C. Some advantages include the elimination of oxide scale formed by heating the joint. But I just found out after they didnt braze with nitrogen. Its a good idea to experiment with flow rates by test brazing parts on the bench. The main guy says that they will do more nitrogen purgeflush to get rid the flakes vacuum will suck the flakes out.

Source: pinterest.com

Source: pinterest.com

REMOVE CORES When you set up you first need to remove your cores in the inlet and outlet of the brazing path. If the lines arent purged then the ash will get swept away by the refrigerant when it is first turned one. The main guy says that they will do more nitrogen purgeflush to get rid the flakes vacuum will suck the flakes out. Im having my unit installed yesterday and from reading through this forum I know the importance of brazing with nitrogen. Once this is done.

Source: youtube.com

Source: youtube.com

When brazing the refrigerant piping only begin brazing after having carried out nitrogen substitution or. I saw nitrogen tank so i didnt remind them of that. This video was shot to show the effects of brazing copper pipe 15 while flowing nitrogen and when not flowing nitrogenthis is NOT a how to braze video and it. Flakes formed during brazing without a nitrogen purge will separate from the tubing wall to circulate with the refrigerant and oil eventually forming restrictions. A small hole in a cap at the end of the line will allow the nitrogen to escape.

Source: youtube.com

Source: youtube.com

When brazing the refrigerant piping only begin brazing after having carried out nitrogen substitution or. Ash forms on the inner and outer surfaces as a result. With six percent silver this type of brazing rod starts to melt at 1190 C. After cleaning apply flux to the inner and outer joints. Keep in mind that you need to FLOW nitrogen not PRESSURIZE with nitrogen while brazing otherwise you never get the joints to hold.

Source: amazon.com

Source: amazon.com

Section the finished assemblies and inspect for a clean inner tube wall. The system did also run flat. They indicate that failure to do so in a R410A system is worse as the oils may loosen the build up causing it to travel and block. But in my. Flakes formed during brazing without a nitrogen purge will separate from the tubing wall to circulate with the refrigerant and oil eventually forming restrictions.

Source: youtube.com

Source: youtube.com

After cleaning apply flux to the inner and outer joints. The manufacturer suggests that nitrogen be used while solderingbrazing joints to reduce build up inside the pipes from oxidation. The leaks were tracked down to a manufacturing fault where the refrigerant line splits 4 ways in close proximity to the condenser. When youre doing this youve got to constantly. Brazing without nitrogen create oxides in the piping no matter how good you are and I know that they arenÂt flushed out through his manifold gauge set much less the little restrictive and blocking Schrader valves.

Source: pinterest.com

Source: pinterest.com

When youre brazing youre going to need to heat your lines up until theyre basically glowing red. REMOVE CORES When you set up you first need to remove your cores in the inlet and outlet of the brazing path. Section the finished assemblies and inspect for a clean inner tube wall. If this is allowed to remain in the system the oil and refrigerant will eventually loosen this so it will collect on strainers in the inlets to TXVs and driers causing a restriction. PurgeBrazing heat causes the copper tubing to oxidize.

Source: pinterest.com

Source: pinterest.com

PurgeBrazing heat causes the copper tubing to oxidize. Once this is done. Now im freaking out. Section the finished assemblies and inspect for a clean inner tube wall. Take this step during installation and.

Source: pinterest.com

Source: pinterest.com

Set the regulator for a low pressure typically 1 to 2 psi is recommended for this process. Using gas to purge in my eyes is worthless wasteful and. If you brazing is done without nitrogen gas blowing a large amount of oxide film develops inside the piping and could cause system malfunction. Set the regulator for a low pressure typically 1 to 2 psi is recommended for this process. Before brazing or soldering any pipe it is important to fit the pipe and clean it.

Source: pinterest.com

Source: pinterest.com

The nitrogen and argon are inert and while we dont want much of them inside a refrigeration system they dont react with the oil refrigerant and metals in the system like oxygen and water vapor can and often do. Flakes formed during brazing without a nitrogen purge will separate from the tubing wall to circulate with the refrigerant and oil eventually forming restrictions. After cleaning apply flux to the inner and outer joints. Ash forms on the inner and outer surfaces as a result. It is very thin and forms in the area of the heated joint so it is just not the joint but also the pipe itself where this can form.

Source: fleurus-electro.com

Source: fleurus-electro.com

If this is allowed to remain in the system the oil and refrigerant will eventually loosen this so it will collect on strainers in the inlets to TXVs and driers causing a restriction. Take this step during installation and. When brazing the refrigerant piping only begin brazing after having carried out nitrogen substitution or. However a tinsilver alloy is a viable option and offers some distinct advantage over brazing. Ash forms on the inner and outer surfaces as a result.

Source: youtube.com

Source: youtube.com

Its a good idea to experiment with flow rates by test brazing parts on the bench. However a tinsilver alloy is a viable option and offers some distinct advantage over brazing. If you brazing is done without nitrogen gas blowing a large amount of oxide film develops inside the piping and could cause system malfunction. Theres drier filter to. A small hole in a cap at the end of the line will allow the nitrogen to escape.

Source: tr.pinterest.com

Source: tr.pinterest.com

I saw nitrogen tank so i didnt remind them of that. Purging the lines with nitrogen removes the oxygen and prevents oxidation. Its a good idea to experiment with flow rates by test brazing parts on the bench. But I just found out after they didnt braze with nitrogen. Its not so much the build up of scale on the inside of the pipes that is the issue see R-22 systems and other CFC refrigerants but its the oil that HFC systems use that act as essentially a degreaser and strip the scale away from the pipes and clog your driers metering devices etc.

Source: pinterest.com

Source: pinterest.com

Section the finished assemblies and inspect for a clean inner tube wall. Without the use of nitrogen during any brazing operation you will form copper oxide in the pipe. Using gas to purge in my eyes is worthless wasteful and. I saw nitrogen tank so i didnt remind them of that. There is also a definite plus in not having to carry the nitrogen.

Source: achrnews.com

Source: achrnews.com

When we call nitrogen dry nitrogen we just mean that it is nitrogen vapor alone with no water vapor or oxygen mixed with it. If the lines arent purged then the ash will get swept away by the refrigerant when it is first turned one. When we call nitrogen dry nitrogen we just mean that it is nitrogen vapor alone with no water vapor or oxygen mixed with it. A small hole in a cap at the end of the line will allow the nitrogen to escape. Now im freaking out.

Source: pinterest.com

Source: pinterest.com

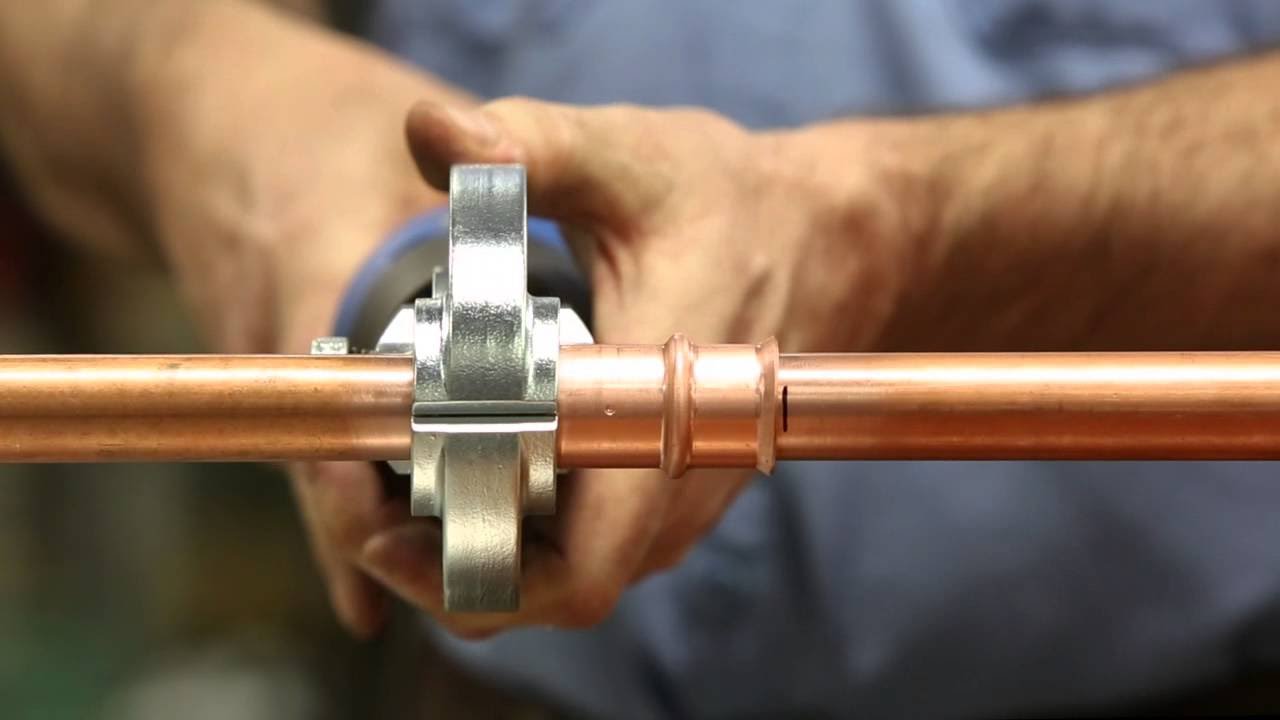

Its not so much the build up of scale on the inside of the pipes that is the issue see R-22 systems and other CFC refrigerants but its the oil that HFC systems use that act as essentially a degreaser and strip the scale away from the pipes and clog your driers metering devices etc. Cut the pipe to the desired length with tubing cutters and ensure it has a good fit. Flakes formed during brazing without a nitrogen purge will separate from the tubing wall to circulate with the refrigerant and oil eventually forming restrictions. But I just found out after they didnt braze with nitrogen. REMOVE CORES When you set up you first need to remove your cores in the inlet and outlet of the brazing path.

Source: pinterest.com

Source: pinterest.com

Flakes formed during brazing without a nitrogen purge will separate from the tubing wall to circulate with the refrigerant and oil eventually forming restrictions. PurgeBrazing heat causes the copper tubing to oxidize. If the lines arent purged then the ash will get swept away by the refrigerant when it is first turned one. For joining copper lines we usually use brazing rods that are made out of a copper-phosphorous combination. Once this is done.

Source: pinterest.com

Source: pinterest.com

Before brazing or soldering any pipe it is important to fit the pipe and clean it. If parts are overheated and flux is difficult to remove mechanical clean-ing may be required. Brazing without nitrogen create oxides in the piping no matter how good you are and I know that they arenÂt flushed out through his manifold gauge set much less the little restrictive and blocking Schrader valves. The leaks were tracked down to a manufacturing fault where the refrigerant line splits 4 ways in close proximity to the condenser. REMOVE CORES When you set up you first need to remove your cores in the inlet and outlet of the brazing path.

This site is an open community for users to submit their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site beneficial, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title brazing refrigerant lines without nitrogen by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.